RICHI MACHINERY

About RICHI MACHINERY

RICHI MACHINERY is a leading global manufacturer specializing in feed pellet machines, extruders, wood pellet machines, and biomass pellet equipment. With over 30 years of manufacturing expertise and project experience across more than 140 countries and regions, we offer complete equipment sets, engineering design, installation, and turnkey project services to customers worldwide.

Customized Equipment Solution

Tailor-made pelletizing equipment based on raw materials, capacity, formulation, and project goals.

Complete Turnkey Project

Full-process solutions covering plant layout, installation, commissioning, training, and after-sales service.

Full Line & Full Process Supply

One-stop equipment supply from crushing, mixing, pelletizing, cooling, screening to automatic packaging systems.

Global Technical Support

RICHI’s experienced engineers ensure fast installation and long-term stable production.

Customized Solutions for Your Project

For customers across different countries, markets, and product demands, RICHI can quickly provide personalized solutions tailored to your specific project requirements. From individual machines to complete turnkey plants, we design competitive equipment configurations and production processes based on your budget, site conditions, and target market strategy—ensuring fast project delivery, stable operation, and strong commercial returns in your local market.

Main machine recommendations

RICHI MACHINERY focuses on four core equipment : feed pellet machines, extruders, wood pellet machines, and biomass pellet machines. With advanced technology and rich engineering experience, we provide reliable equipment and complete solutions for both feed production and biomass energy industries.

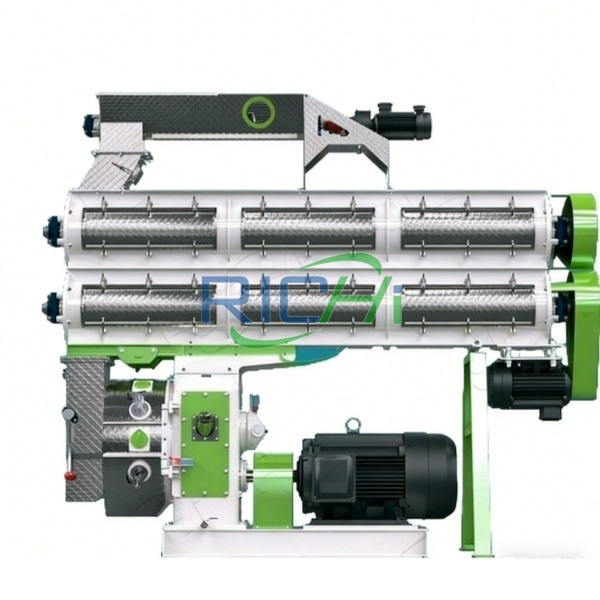

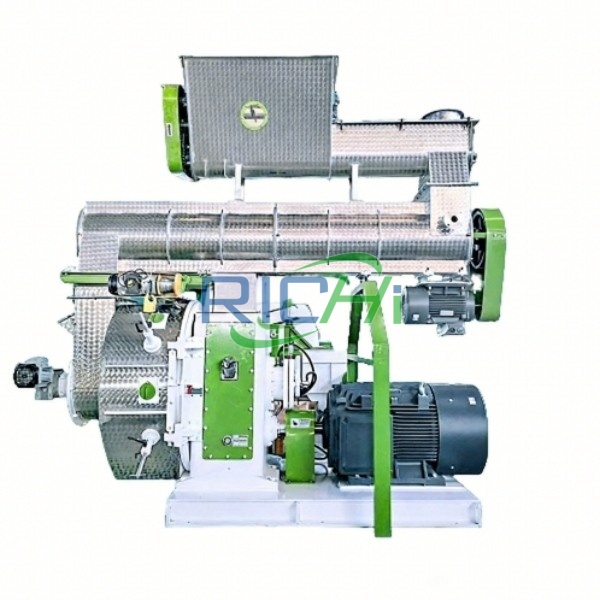

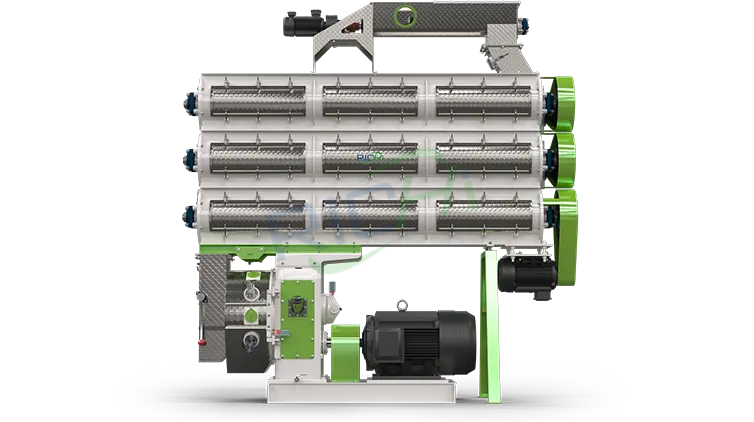

Feed Pellet Machine

High-performance pellet mills for livestock, poultry, aqua feed, and ruminant feed production.

Biomass Pellet Mill

Heavy-duty pellet machines for straw, rice husk, palm waste, and other biomass materials.

Extruder Machine

Advanced extrusion systems for floating fish feed, sinking feed, and pet food.

Customized Machines for Diverse Needs

RICHI MACHINERY offers a wide range of customized pellet machines to meet different feed and biomass processing needs. Each machine is designed for specific raw materials, animal types, and production goals, ensuring efficient, stable, and high-quality output.

Where Our Machines Are Used?

RICHI MACHINERY provides advanced pellet machines for a wide range of industries. Our equipment is designed to meet the unique demands of each production scenario, ensuring high efficiency, stable performance, and consistent product quality. From animal feed to biomass and pet feed, our machines support diverse applications worldwide.

Animal feed production line

RICHI’s animal feed production lines are suitable for poultry, livestock, ruminants, aquaculture, and pet feed production. The process typically includes raw material grinding, mixing, conditioning, pelletizing, cooling, and packaging, producing high-quality feed pellets with consistent size and nutrition.

wood pellet factory

Wood pellet lines convert forestry residues into sustainable fuel pellets. Typical production steps include shredding, drying, pelletizing, cooling, and packaging, providing high-density and uniform wood pellets for heating or industrial use.

Organic Fertilizer Production Line

Organic fertilizer lines convert composted organic materials into nutrient-rich pellets, supporting sustainable agriculture.

Aquatic Feed Pellet Plant

Fish feed lines using extruders produce floating or sinking pellets tailored to different aquatic species, improving feed efficiency and supporting healthy aquaculture growth.

Cat Litter production line

Cat litter lines produce safe, absorbent, and uniform pellets, ensuring hygiene and comfort for pets.

Auxiliary Equipment In Production Line

RICHI MACHINERY provides a complete range of auxiliary equipment to support efficient and stable operation of feed and biomass pellet production lines. From material handling to packaging, our auxiliary machines ensure smooth workflow, reduce labor costs, and improve overall production quality.

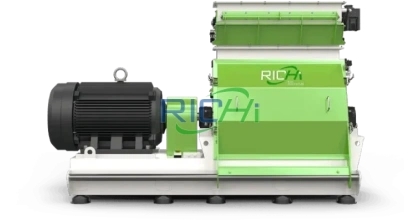

Crusher

Efficiently crushes raw materials like grains, straw, and biomass residues to the required size for pelletizing.

Mixer

Ensures uniform blending of different raw materials and additives for consistent pellet quality.

Dryer

Reduces moisture content of raw materials or pellets to improve pellet density and stability.

Cooler

Lowers pellet temperature after extrusion or pelletizing to maintain shape and quality.

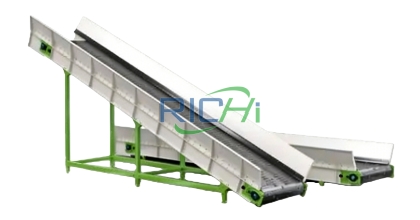

Conveyor

Transfers materials between production stages efficiently and safely.

screening Machine

Separates fine powder and removes defective pellets to improve pellet uniformity and overall quality.

batching equipment

Accurately weighs and feeds raw materials for consistent production ratios.

Packing Machine

Automatically weighs and packs pellets into bags for storage and transport.

Successful Turnkey Projects

Henan RICHI Machinery Co., Ltd. was established in 1995, has been committed to providing customers with turnkey services of feed processing machinery and engineering, biomass pellet production line, steel

RICHI machinery video

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines.

Latest Updates on RICHI MACHINERY Worldwide

Stay connected with RICHI MACHINERY’s global activities. We continue to advance new feed, biomass, and wood pellet solutions across different regions, showcasing our ongoing progress, installations, and delivery achievements around the world.

RICHI Wood Pellet Press Delivered to Poland

A complete wood pellet press solution was delivered on schedule to Poland, supporting clean energy production and efficient forestry residue utilization.

New Biomass Pellet Production Project Advances in Bangladesh

RICHI has recently completed a key stage of a biomass pellet project in Bangladesh. It has completed installation and initial testing and is expected to enter full operation soon.

Feed Production Line Put into Operation in Uzbekistan

The newly installed RICHI feed production line in Uzbekistan has officially entered operation and is performing with stable, reliable output.

Aquatic Feed Line Installation Progress in Russia

The installation of a new aquatic feed line in Russia is currently underway, with equipment being assembled and adjusted on site. Another batch of related equipment is scheduled for delivery soon.

RICHI Machinery

Founded in 1995, RICHI MACHINERY has evolved into a globally recognized manufacturer of pellet machines and complete pellet production line solutions. For nearly three decades, we have supported clients in more than 140 countries and regions, completing over 2,000 customized and turnkey projects across the animal feed, biomass energy, wood pellet, and organic fertilizer industries.

With a team of 200+ engineers and technicians, RICHI integrates every stage of project delivery—from process design and equipment manufacturing to installation, commissioning, and long-term technical support. Our fully unified system allows customers to work with one experienced partner, ensuring efficient project execution, consistent quality, and reliable operation for years to come.

30+

years

Manufacturer

140+

Exports Countries

30+

Patented Technologies

60000+

㎡

Factory Area

Why Choose Us

We are committed to delivering stable, transparent, and consistently high-quality service to customers worldwide. From pre-sales consulting to project delivery and long-term operation support, the RICHI professional team stands with you at every stage to ensure smooth operation and lasting value of your pellet production project.

We have quality service

We do more than manufacture machines, also provide full project services to ensure smooth startup and long-term stable operation.

Consultation

We offer early-stage needs assessment, capacity evaluation, and investment guidance.

Process Design

Optimal process design tailored to raw materials, outputs, and market needs.

Customized Solutions

Tailor-made configurations based on budget, site, power, and industry standards.

Manufacturing

Standardized production for stable, efficient, and durable machines.

Quality Testing

Full inspection and trial-run testing to ensure ready-to-run delivery.

Installation & Commissioning

On-site or remote guidance for fast and smooth startup.

Operator Training

Systematic training in operation, maintenance, and safety.

After-Sales Support

Fast-response support to reduce downtime and maintain stable production.

Spare Parts Supply

Long-term availability of spare parts with global delivery.

System Upgrades

Capacity expansion, energy-saving, and smart upgrades for better performance.