Biomass pellet mill for sale

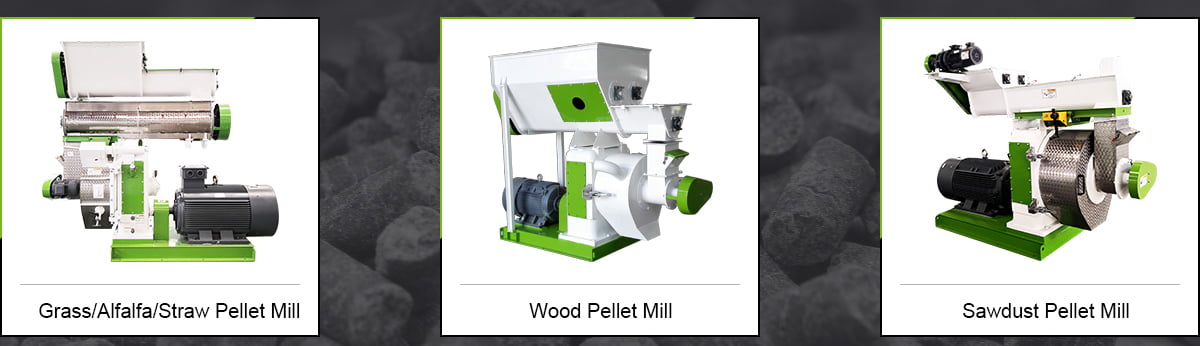

RICHI Machinery, with more than 20 years of experience, specializes in biomass pellet mill for sale, which is recycling different biomass wastes to produce 6-12mm fuel pellets. Due to environmental requirements, biomass pellets have become a good alternative to diesel or coal. The biomass pellet machine has attracted the attention of most users around the world due to its low investment, fast return on investment, and low risk.

- Capacity: 1-12T/H

- Power: 22-280KW

- Suitable raw materials: rice husk, corncob, peanut shell, bagasse, cottonseed shell, animal manures, etc

- Finished pellets: 6-12mm

The working principle of the biomass pellet mill for sale

The working process is that the mixed powder with a water content of no more than 15% enters the conditioner. After tempering, the temperature of the mixed powder can reach 65-85 ℃, and the humidity can reach 14-16%. Then the straw, sawdust or rice husk, and other raw materials are compacted and extruded out of the ring die hole under the high-temperature and high-pressure environment in the granulation chamber. Through the extrusion and friction generated during the movement of the ring die and the pressure roller, the materials finally form regular and dense fuel pellets.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The various capacities of biomass pellet making machine

A biomass pellet making machine is a kind of equipment that converts biomass into energy and is used to process various biomass raw materials into high-strength pellet fuel. RICHI Machinery can provide you with a 0.3-12T/H wood pellet making machine.

MZLH320 biomass pellet making machine

- Capacity: 0.3-0.5T/H

- Main power: 22KW

MZLH350 biomass pellet machine

- Capacity: 0.5-0.7T/H

- Main power: 37KW

MZLH420 biomass pellet machine

- Capacity: 0.8-1.5T/H

- Main power: 90KW

MZLH520 biomass pellet machine

- Capacity: 2-2.5T/H

- Main power: 132KW

MZLH768 biomass pellet machine

- Capacity: 2.5-4T/H

- Main power: 250KW

MZLH858 biomass pellet mill for sale

- Capacity: 4-5T/H

- Main power: 280KW

The specific parameters of the equipment are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Various raw materials suitable for the biomass pellet mill

As we know, biomass pellets are processed fuels. What are the raw materials of biomass fuel pellets?

Agricultural resources

It mainly includes waste in agricultural production and processing. Wastes, such as rice husk, corncob, peanut shell, bagasse, and cottonseed shell, are generated during the processing of agricultural products. These wastes are relatively concentrated, easy to collect and treat, and can be used as raw materials to produce biomass fuel.

Urban organic solid waste

It mainly includes household waste and commercial service waste.

Animal manures

Chickens, pigs, cows, and cows have the poor digestive capacity, and can only consume 25% of the nutrients. The other 75% of the nutrients in the feed are excreted with the feces, so the feces contain nitrogen, phosphorus, potassium, organic matter, amino acid, protein, and other components. The pellet produced from animal manures can be used as organic fertilizer.

Straw pellet mill

Capacity:

1-12T/H

Main Power:

22-280KW

Hemp pellet machine

Capacity:

1-12T/H

Main Power:

22-280KW

bamboo pellet mill

Capacity:

1-12T/H

Main Power:

22-280KW

Hop pellet machine

Capacity:

1-12T/H

Main Power:

22-280KW

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

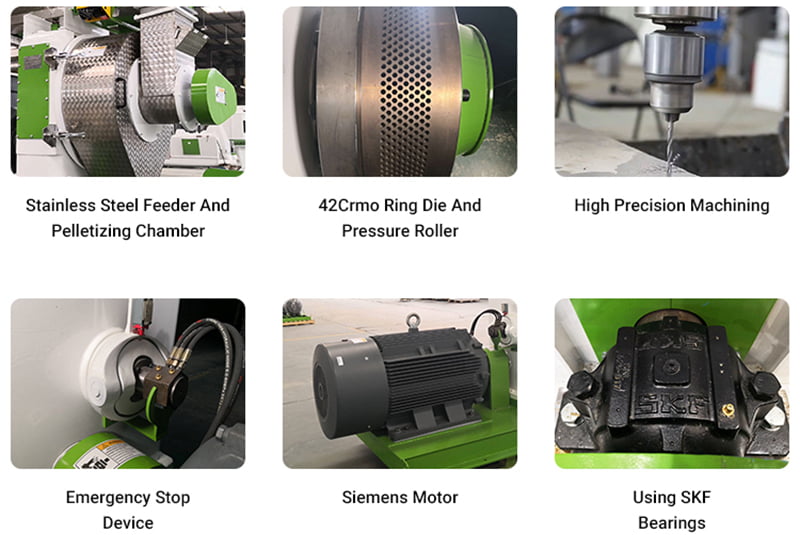

The highlights of the biomass pellet machine

- The lubrication part of the biomass pellet making machine adopts a timed oil injection automatic lubrication system. An automatic lubrication device protects the bearing. The biomass pellet mill for sale has completely solved the problem of pressing roller lubrication.

- The active gear of the biomass pellet machine adopts the high-precision gear drive. Production is more stable, and the production is about 15% higher than the belt type.

- Feed adopts frequency conversion and speed regulation feeding to ensure uniform feeding.

- Stainless steel door cover and feeder. The international advanced manufacturing process can be tailored for your various biomass pellet making machine for a variety of materials ring dies, which extends the life of the equipment, and improves the product quality.

- The biomass pellet making machine can achieve 24 hours of continuous operation. Don’t worry about overheating and lubrication.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The main parts of the biomass pellet mill for sale

Force feeder

Because the biomass crushing materials are too light, so it is difficult to enter the pelletizing chamber, so the biomass pellet making machine is equipped with a force feeder, to make the pelletizing process normal working.

Steam discharging outlet

In the pelletizing chamber, the granulation process will produce a lot of steam. In order to keep the biomass pellet making machine good working, so there is a steam discharging outlet to connect with the draught fan and cyclone to reduce the temperature in the chamber.

Pelletizing chamber

Through the pressure between the ring die and rollers, the crushing materials are pressed into pellets.

Cutting device

By adjusting the distance between the cutter and ring die to get the different lengths of final pellets.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The cases about the biomass pellet making machine

A biomass pellet machine is a pelletized fuel molding machine developed by RICHI Machinery based on the market demand, which uses corn straw, rice straw, rice bran, sawdust, and other agricultural wastes as raw materials. The pellets made by the equipment can be used in fireplaces, boilers, and biomass power plants. Due to its wide application, RICHI biomass pellet mills export all over the world.

Ukraine

Small capacity biomass pellet machine

- Date: July 2019

- Model: MZLH320

- Raw materials: beech wood

- Size of the finished pellets: 6-8mm pellets

- Workshop size (L*W*H): 16m*13m*6m

Indonesia

Biomass pellet mill for sale in Indonesia

- Capacity: 1T/H

- Model: MZLH420

- Raw materials: sawdust

- Size of the finished pellets: 8mm

- Workshop size (L*W*H): 20m*10m*15m

South Africa

South Africa biomass pellet machine

- Date: May 19th, 2021

- Model: MZLH520

- Capacity: 2-2.5T/H

- Raw materials: wheat straw

- Size of the finished pellets: 3mm, 5mm

Canada

biomass pellet machine

- Date: August 2018

- Capacity: 2-3T/H

- Raw materials: 50% moisture wood chips and 50% moisture sawdust

- Size of the finished pellets: 6-12mm pellets

Austria

5T/H biomass pellet making machine

- Capacity: 5T/H

- Model: MZLH520

- Raw materials: sawdust and wood shavings

- Size of the finished pellets: 4mm biomass pellets

USA

USA biomass pellet mill for sale

- Capacity: 10T/H

- Model: MZLH768

- Raw materials: wood wastes from furniture factories, paper mills, and other factories

- Size of the finished pellets: 6-12mm pellets

The main equipment of the complete biomass pellet plant – biomass pellet making machine

The professional machinery for making biomass pellets are called a biomass pellet machine, which can process all kinds of combustible biomass raw materials without adding any additives to produce biomass pellets.

How to select biomass pellet production equipment? First of all, we need to understand the production process of biomass pellets. Different types of raw materials require different equipment. For example, the equipment used for logs and sawdust is different. The log needs to be roughly broken, crushed, and then dried for granulation, which requires a wood chipper machine, wood crusher machine, dryer, biomass pellet making machine, cooling machine, packaging machine, etc. If the moisture of sawdust is suitable, it can be directly granulated, which requires only screening machine, biomass pellet mill for sale, cooling machine, packaging machine, etc.

RICHI Machinery not only provides 1-12T/H biomass pellet machine but also offer clients a full set of production processes and equipment for biomass pellet plant, including screening, crushing, drying, mixing, granulating, cooling, packaging, and other links of raw materials. The RICHI biomass pellet plant has the characteristics of easy operation, stable performance, and convenient maintenance. The whole line is highly automated. The feeding amount of raw materials does not need manual control. The biomass pellet machine is fed with variable frequency speed regulation, and the finished products are automatically weighed.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Why is RICHI Machinery a professional manufacturer of biomass pellet plants?

A biomass pellet making machine is a kind of biomass energy production equipment. It mainly uses biomass such as sawdust, straw, rice husk, and bark from agricultural and forestry processing as raw materials. Through processing, it is solidified into high-density particulate fuel, which is very green. Then how to select an appropriate biomass pellet machine? You can believe RICHI Machinery.

More than 25 years of experience

RICHI Group has our own manufacturing plant and enjoys a good reputation. Also, we have our own factory. Welcome to RICHI factory!

High-quality assurance

As a manufacturer, RICHI always chooses high-quality materials to prolong its service life and improve efficiency. The biomass particle mill sold by RICHI uses stainless steel as the main material. It has good corrosion resistance.

Customer-oriented service RICHI biomass pellet mill for sale

- Send us your requirements. We can provide you with cost-effective layout plans for free.

- Provide sample test free of charge.

- We test raw materials free of charge. You can send the sample to us, and we will provide you with the data.

- We design process flow charts for you free of charge. If you have an existing factory, you can provide the area for detailed design.

- We have a professional service team to provide you with the most appropriate biomass pellet plant equipment and satisfactory service.

- We provide complete installation of biomass pellet plant and staff training for free, so your workers can operate the equipment correctly and smoothly.

- We have an experienced and skilled R&D team to continuously improve the configuration and technology.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

FAQ about the biomass pellet mill for sale

What is the future prospect of biomass pellet machine?

The new energy technology of biomass pellet making machines and equipment can crush the agricultural and forestry production and processing wastes such as wood residue, straw, chaff, tree roots, and other biomass as raw materials, and then suppress them into biomass pellet fuel.

Agricultural and animal husbandry wastes are the three elements of biomass resources. And this kind of biomass resource can also be used in the recycling system.

Biomass pellet mill for sale will make deep use of this energy supply to produce energy conservation and environmental protection industries that process biomass pellet fuel and reduce the anxiety of power energy supply. It has a great industry prospect.

Biomass pellets have high relative density, which is an ideal fuel to replace gasoline. It can save resources and reduce emissions. It has excellent economic and social economic benefits and is an efficient and clean renewable resource.

Why do you need to buy a biomass pellet making machine?

- It can make full use of biomass waste.

- Profitable and environmentally friendly.

- High output and return on investment.

- The products are widely used and very popular in the market.

- High efficiency, advanced technology, and good quality.

- Low power consumption.

- Long service life.

We all know that biomass pellets are good, but what is the best? Of course, the wood pellet making machine is good. So what are the advantages of the wood pellet making machine?

- The relative density of fuel particles produced by biomass pellet machines is about ten times that of general materials, the relative density of shaped particles exceeds 1100kg/m³, and the fuel characteristics have been greatly improved.

- The size is small and the net weight is large. The particles produced by the raw materials after layer-by-layer production and processing are only about 1/30 of the ordinary materials. Transportation and storage are very convenient.

- Granules can be used for civil heating equipment and domestic energy, and can also replace raw coal as the fuel of boilers, reducing air pollution, and improving the comprehensive utilization rate of straw.

With the further implementation of the new national policy, the range of remediation of electric energy and natural environment is also increasing. Biomass pellet machines are also used in more and more industries, and biomass pellets are also used in a large number of industries.

How to choose a biomass granulator?

More and more people want to enter the biomass pellet production industry. The first thing you consider must be the cost to invest in the biomass pellet mill. When you want to know the total price set at a high investment ratio, please consider the following factors.

01 How much capacity do you plan to produce every day

Tell us what capacity you need or how many raw materials you plan to handle each day. We will provide good suggestions according to your needs. There are various types of biomass pellet mills.

02 Demand for relevant equipment to improve granulation quality or efficiency

Crushers and dryers are used to process raw materials. This step makes the particle quality better. Cooling machine and packaging machine help customers shorten delivery time and reduce labor costs.

Where do biomass particles come from?

Biomass particles are made of a variety of raw materials, such as wood, sawdust, rice straw, rice husk, grass, peanut shell, corn straw, wheat straw, cotton stalk, corn cob, branches, bagasse, bark, furfural residue, edible fungus residue, traditional Chinese medicine residue, and other various biomass solid wastes.

Different raw materials are used to make different granules. When selecting raw materials, please pay attention to the following factors:

01 Size of raw materials

Except for wood chips, most biomass raw materials are larger than 2cm, so they need to be crushed before granulation. For example, a crusher or hammer crusher can make long and large wood chips into 3-5 mm wood flour, which is the best size for manufacturing biomass particles.

02 Moisture content

Water content in raw materials is an important factor affecting the quality of biomass particles. For biomass granulation, the most appropriate moisture content is 12%-18%. If the moisture content of the raw material is higher than 15%, a dryer is required.

03 Purity

Some raw materials are pure, but others may contain metal chips or stones, such as sawdust. If these impurities enter the biomass pellet machine, they will undoubtedly damage the roller and ring die of the biomass pellet making machine. Therefore, biomass with particles should be screened before granulation.

If you want to learn about the biomass pellet mill for sale, just send inquiries to us.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production