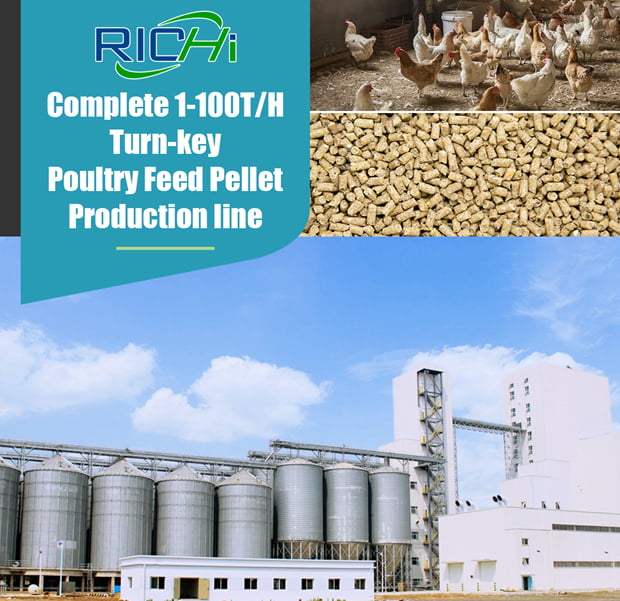

A chicken feed manufacturing plant is a complete chicken feed production line for producing pellets for animals, and supplying animals the basic nutrition. The equipment can be designed according to your different needs. RICHI Machinery can provide various designs to meet customers’ needs. The chicken feed production line provided by RICHI Machinery is CE/ISO/BV certificated and sold well all over the world. RICHI Machinery owns its factory and professional technical team. And we have a professional and highly-skilled after-sales service team and a modern and information-based after-sales management system.

The chicken feed manufacturing plant mainly includes raw material receiving and cleaning systems, crushing systems, batching and mixing systems, granulating systems, cooling systems, screening systems, and finished product packaging systems. The chicken feed production line is specially designed for the production of chicken feed pellets and poultry feed pellets and is widely used in feed plants, farms, fertilizer plants, etc.

According to the specific needs of customers, we can design complete sets of chicken feed processing equipment suitable for broilers, layers, and chickens.

RICHI Machinery can produce the chicken feed manufacturing plant with 1-100t/h capacity. We have a lot of different designs that can be chosen. And we can also specially customize it for you.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

The main sections of the chicken feed production line are crushing, mixing, pelletizing, cooling and packing. The main equipment of a complete chicken feed manufacturing plant are cleaning system, feed grinder machine, feed mixer machine, chicken feed pellet machine, cooling machine, pellet crumbler, vibrating screener, conveying system, storage system, boiler equipment, electric cabinet, etc.

The cleaning system is the first step of a complete chicken feed production line. It mainly focuses on cleaning the impurities of the raw materials. The equipment usually used are powder sieve, drum type pre-cleaner, and permanent magnet sleeve.

The powder sieve is mainly to do the first cleaning in the cattle feed processing plant. It can effectively separate sundries such as paper, stone, and rope mixed in raw materials to ensure normal operation.

The drum-type pre-cleaner is removing large impurities, such as corn cobs, corn leaves, wheat straw, rice straw, rope, paper, clods, and other sundries, in order to protect the machinery from failure or damage.

The permanent magnet sleeve is separating the iron filings from the raw materials. It is suitable for feed plants, grain and oil processing plants, solvent plants, and brewing plants of various sizes.

A feed grinder machine is used to crush the raw materials into powder. It can crush various granular feed raw materials, such as corn, sorghum, wheat, beans, crushed cake and other materials. It is widely used by the large-sized animal feed industry.

This machine is suitable for mixing materials in various industries, such as powder, granular, flaky, and viscous materials in feed industries.

The advantages of the feed mixer machine are:

The chicken feed pellet machine is a key part of the chicken feed manufacturing plant. It can be used to produce baby chicken feed pellets, hens feed pellets, turkey feed pellets, broiler feed pellets, and so on. It is also widely used in animal feed processing plants and animal farms.

The advantages of the chicken feed pellet machine are:

The counterflow cooler series can cool pellets from 80°C to slightly above room temperature for 3°C-5°C, for easier transportation and storage of pellets.

The advantages of the cooling machine are:

It is widely used for crushing poultry pellets and aquatic pellets. Mainly used to produce small-diameter feed pellets for baby chickens and suckling pigs. Because of the pellet feed crumbler, the whole production line can grow 0.8-12mm different particle size feed pellets to meet the feeding needs of different animals.

The vibrating screener is a high-efficiency material grading screen equipment widely used for grain, feed, flour, and food industries to realize material grading.

The advantages of the vibrating screener are:

The conveying system is mainly used to transfer material. Due to different sections, different conveying systems can be used, such as bucket elevator, scraper conveyor, and screw conveyor.

It is used for conveying materials in the vertical direction, and the conveying height can reach 50m.

It is used for horizontal or small angle transportation of high-yield materials, and the length can reach 30m.

It is used for short-distance transportation of materials and can be used at an inclination angle of less than 20°.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The main sections of the chicken feed production line are the crushing and mixing section, pelletizing section, and cooling, and the packing section. The main machines are feed grinder machine, feed mixer machine, chicken feed pellet machine, pellet crumbler, cooling machine, screwing system, conveying equipment, etc.

This step is mainly to remove impurities of raw materials, such as rope, clods, and iron filings, and crush the raw materials into the size needed. Putting the raw material of a specific proportion into the screw conveyor. Then the raw material would be crushed into powder by the hammer mill. After that, the powder would be completely mixed in the animal feed mixer.

The pelletizing section is the most important part of the whole process. This section is to press the powder into particles of a certain size. After mixing, the powder is conveyed into the conditioner by the variable frequency feeder. And in the conditioner, the powder is fused with steam. After reaching a certain temperature and moisture, the powder enters the ring die granulator. Then the powder is strongly squeezed by the ring die and the pressure roller to form granules. Under the strong compression of the ring die and the pressure roller, the granules are formed and then cut into the desired length by the cutter.

The conveyor puts the pellets into the cone bucket. The pellets pass through the cone bucket and are discharged into the cooler. Then the pellets get through the vibrating screener. After sieving, the pellets can be packed.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

The chicken feed manufacturing plant provided by RICHI Machinery is CE/ISO/BV certificated and sold well all over the world. It is favored by the majority of users. RICHI Machinery has clients from more than 100 countries, such as Tanzania, Malawi, Afghanistan, Uzbekistan, Senegal, Rwanda, Gambia, Saudi Arabia, New Zealand, Sudan, Papua New Guinea, Botswana, Cape Verde, Iraq, Australia, etc. If you have something want to learn about, you can visit on-site.

RICHI Machinery has provided thousands of feed manufacturers with chicken feed production lines, poultry and chicken feed plants, and single poultry and chicken feed pellet machines. And hope that in the future we can also help you successfully build an efficient and high-return chicken feed manufacturing plant.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

When raising chickens, it is usually necessary to feed them, so as to promote their normal growth and facilitate higher economic benefits for people. Existing chicken feed is usually packaged directly after processing and production without pelletizing the feed, which makes it difficult to store and transport.

RICHI pellet machine can produce feed pellets that are suitable for chicken. The advantages of the feed pellets are as follows:

Chicken pellet feed is a strip feed made of powdered feed extruded by a chicken feed pellet machine. It is a popular feed form today. In recent years, with the rapid development of the feed industry, pellet feed has been gradually accepted by the majority of farmers. Therefore, for chicken feed manufacturers or poultry farms, the establishment of a chicken feed plant or the purchase of a chicken feed manufacturing plant is very promising.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

Do you get into trouble when you want to build a chicken feed manufacturing plant? Do you hesitate how to select the proper equipment? Don’t be anxious. You can choose based on the following aspects.

Chicken feed manufacturing plant is specializing in the production of feed. It can produce different feed pellets, such as baby chicken feed pellets, hens feed pellets, laying chicken feed pellets, broilers feed pellets, turkey feed pellets, etc.

RICHI chicken feed production line is used to produce feed pellets of different sizes, such as 1.5mm baby chicken feed pellets, 3-4mm broiler and layer feed pellets, and other sizes you need. It can be customized according to your detailed requirements.

If the feed pellets you produce are only for your own farm or animals, you do not need a packing machine. If you produce feed pellets for sale, then you have the need for a packing machine.

An important step in choosing a high-quality chicken feed plant manufacturer is to find a reliable brand of feed pellet mill. RICHI Machinery has its own factory and professional production equipment. It is an industrial group that mainly focuses on feed pellet machinery, and also involves biomass pellet energy machinery, organic fertilizer pellet machinery, and parts.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

RICHI Machinery pursues the purpose of product quality first. The main parts and wearing parts are made of high-quality wear-resistant materials, coupled with advanced processing technology.

We can provide to build different types of chicken feed plants to meet different chicken feed production needs. We also provide various solutions for customers according to their needs, raw materials, production capacity, etc. Not only can produce feed grinder machines, feed mixer machines, chicken feed pellet machines, feed batching equipment, puffing equipment, and automatic electric control equipment, but also can develop from a single machine to complete sets of feed equipment. With more than 20 years of experience in the industry, RICHI Machinery can provide customers with different recommendations. The equipment is sold in many countries and regions in the world, such as Europe, Asia, Oceania, North America, South America, the Middle East, and Africa.

If you want to build a chicken feed manufacturing plant, the advantage of choosing us is that RICHI Machinery can help you:

Also, RICHI Machinery can provide you with feed machinery design, feed machinery installation, training, and after-sales service.

RICHI Machinery has a professional technical team. On the basis of site survey and planning for customers, provide customers with detailed project design scheme, feed equipment list, project cost, design site foundation drawings, and design special feed production process.

RICHI Machinery has a complete technical training and guidance system. After installation, professional engineers will train operators and guide the handling of common problems to ensure the stable operation of the system.

RICHI Machinery always focuses on the field of feed machinery processing and has a modern and information-based after-sales management system and a professional and highly-skilled after-sales service team. From the supply of common accessories, and equipment maintenance to repair, we provide customers with a “one-stop” service to solve their problems and worries.

RICHI Machinery, as a chicken feed manufacturing plant manufacturer, would offer you all-around service. If you want to learn more about poultry feed pellet machines, just contact us.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

In the process of raising chickens, farmers often choose to match their chickens with chicken feed for the sake of reducing costs and improving nutrition. As we all know, chicken feed is the basic guarantee for the healthy growth of chicken flocks on chicken farms. There are also a lot of requirements for the processing of chicken feed. However, some farmers often pollute the chicken feed due to improper processing methods, which is not conducive to the normal growth of chicken flocks on chicken farms, and also increases the cost of raising chickens for farmers.

The chicken feed manufacturing plant is to make corn, soybean, maize, grass, and wheat powdery into 2-12mm chicken feed pellets. After crushing and mixing the raw materials, the chicken feed pellet machine can process raw materials into nutritious feed pellets for the chicken. The feed pellets produced by RICHI pellet machine have the following advantages.

First of all, after the sterilization of high-temperature steam, the possibility of mildew and insects in the feed is reduced, and the palatability of the feed is improved. Secondly, the nutrition is comprehensive, and animals are not easy to picky about food, which reduces the separation of nutrients and ensures the daily supply of nutritionally balanced feed. Thirdly, the reduction of the volume of feed pellets is easy for feeding. Also, it can reduce labor consumption.

RICHI Machinery can provide you with a complete chicken feed manufacturing plant. We can help you with plan design, workshop layout, equipment production, installation, training to after-sales. If you are intending to build a chicken feed plant, just contact us.

In general, users choose different equipment and corresponding power according to their own production capacity and product types.

With in-depth research on the feed industry, more and more scientific researchers and manufacturers are improving the quality of raw materials and optimizing formulations, while taking feed processing technology as an important way to improve product quality. The hardness of feed pellets is an important index of the appearance quality of pellet feed. And it is also found that the particle hardness of pellet feed has a certain influence on the production performance of livestock and poultry in the feeding process of some chicken farms. Therefore, how to regulate the particle hardness of pellet feed is a problem that some manufacturers and scientific researchers are actively exploring.

Throughout the whole process of feed pellets production, in addition to the feed formula, the process that affects the hardness of the feed pellets are: the crushing process of raw materials, the steam conditioning process, and the selection of the ring die in the pelletizing process.

The decisive factor for the hardness of the pellets in the crushing process is the size of the crushed raw materials. The impact of crushing raw materials’ size on the hardness of the pellets directly affects the conditioning process and granulation process. In actual production, according to the production performance of different animals and the size of the ring die aperture, crushing size requires to make appropriate adjustments.

Generally speaking, in the process of the chicken feed manufacturing plant, the finer the crushing size of the raw material, much easier the starch paste in the conditioning process, the much stronger the bonding effect in the raw materials, and the much greater the hardness of the pellets.

Steam conditioning is a key process in pellet feed production, and the conditioning effect directly affects the internal structure and appearance quality of pellets. Steam quality and conditioning time are two important factors that affect the conditioning effect. High-quality and dry saturated steam can provide more heat to raise the temperature of the material. The longer the conditioning time, the higher the degree of starch paste, and the greater the hardness of the feed pellets.

For general livestock and poultry, the conditioning temperature is kept at 70-80℃ by adjusting the amount of steam added, and the conditioning time is controlled by changing the length of the conditioner, the angle of the paddle, and the rotational speed to about 30 seconds. For fish materials, it generally adopts a double or multi-layer conditioner to increase the conditioning temperature and extend the conditioning time. It is more conducive to improving the stability of fish pellets in the water, and the hardness of the pellets also increases accordingly.

In the processing of chicken feed plants, the factors affecting the hardness of the pellets are far more than these. As more and more scientific and technical workers are enthusiastic about feed processing technology research, more and more methods to regulate the hardness of the pellets are mastered. RICHI Machinery can provide various chicken feed manufacturing plants to produce different feed pellets to suit the needs of animals. If you have this intention, just send an inquiry to us.

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production