Grass pellet mill

A grass pellet mill is a kind of pelletizer developed for grass. Pasture generally refers to grass or other herbs used by livestock. The grass pellet machine is suitable for pressing materials that are difficult to bond and shape and can solidify agricultural and forestry processing wastes such as grass and pasture into granules through processing.

- Capacity: 0.7-40T/H

- Main power: 22-280KW

WHATSAPP

+86 18574103366

The video of the grass pellet making machine

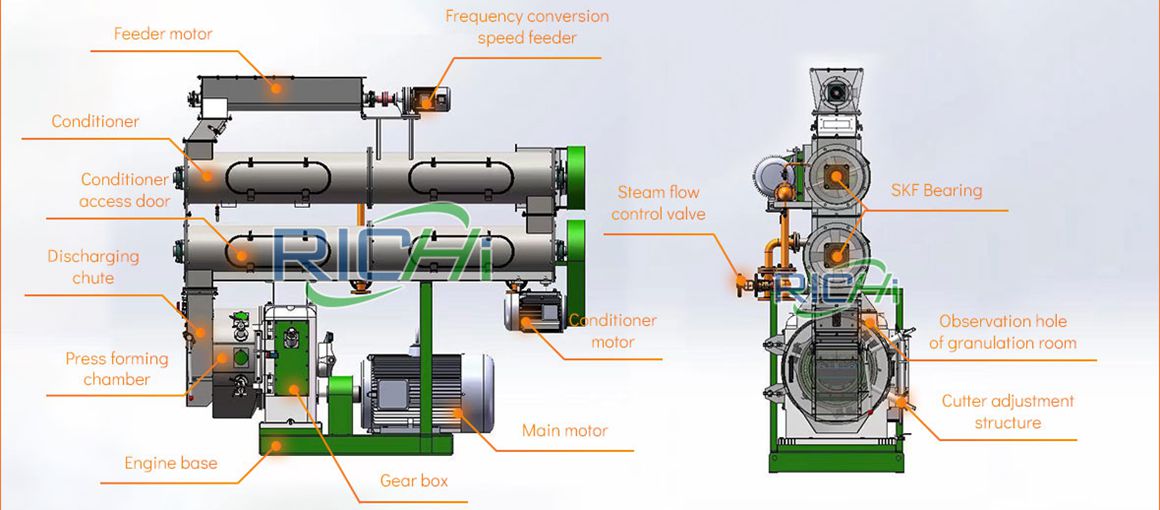

The grass pellet mill is a special Forcing feeding structure for grass feeding in the pressing room. The feeding uniform main drive adopts a high-precision gear drive, and its output is about higher than that of the belt drive type. The ring die adopts a quick-release hoop-type drive part, which uses imported high-quality bearings, with long service life. Low noise feeding control adopts frequency conversion speed regulation to ensure uniform feeding. Convenient operation, reliable sealing, stable torque, high vibration absorption, and isolation strength, and low labor intensity.

The advantages of the grass pellet mill

01

The utility model has the advantages of convenient operation, simple process, etc. The use of powdered feed and grass powder can be used for granulation without (or a little) liquid addition. Therefore, the moisture content of pellet feed is basically the moisture content of materials before pelleting, which is more conducive to storage.

02

The material can be dried in and out without drying. It is driven by differential and universal joint and equipped with motor. It has low energy consumption, high output, convenient operation and low noise.

03

The feed granules produced by dry material processing have high hardness, smooth surface and internal ripening, which can improve the digestion and absorption of nutrients. The particle formation process can denature the resistance factors in grains and beans, reduce the adverse effects on digestion, kill various parasitic eggs and other pathogenic microorganisms, and reduce various pests and digestive system diseases. Compared with mixed powder feed, it can achieve higher economic benefits.

04

The new process of extrusion granulation and polishing is adopted to solve the key technical problems such as low addition of organic raw materials, difficult granulation and drying and crushing of raw materials. During the pressing process, high temperature and high pressure are generated. The feed has a strong paste flavor and is hard, which conforms to the characteristics of rodents of pigs, cattle and sheep. The palatability of the feed is improved, and it is easy to eat. The nutrient absorption conversion rate is increased by 300%. It is non-toxic and sterile.

05

It is convenient to adjust the particle size to produce cylindrical feed particles. Adapt to different materials and ensure the pressing effect. The compression molding of sawdust, corn straw, etc. requires a lot of pressure. In similar granulating equipment, the roller part is the central part of the whole equipment, and alloy steel is used to improve the service life of the roller.

06

It is widely used for granulation in animal husbandry, large, medium and small farms, feed mills and other units, and is an ideal equipment for animal husbandry.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The specific parameters of the grass pellet machine

Grass pellet mill

The grass pellet making machine is a special forced-feeding structure for forage in the pressing room. The main drive for uniform feeding is a high-precision gear drive, and its output is about higher than the belt drive type. The ring die adopts a quick-release hoop-type transmission part, which adopts imported high-quality bearings and has a long service life. Low noise feeding control adopts frequency conversion speed regulation to ensure uniform feeding. Convenient operation, reliable sealing, stable torque, high vibration absorption, isolation strength, and low labor intensity.

- Capacity: 0.7-40T/H

- Main power: 22-280KW

The specific parameters of the equipment are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Cases Of The grass pellet making machine

RICHI Machinery, as a manufacturer of ruminant feed pellet production lines, can provide you with various designs according to your different needs. With more than 25 years of experience, RICHI Machinery owns its factory and professional technical team. The ruminant feed pellet production line can produce 2-12mm feed pellets from corn, grass, wheat bran, rice bran, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc.

The grass pellet mill for cattle In Tanzania

- Capacity: 1-2T/H

- Raw materials: corn, soybean meal, oil

- Finished pellet size: mash feed, and 3mm, 4mm, and 6mm cattle feed pellets

- Workshop size: 13m*4m*8m (L*W*H)

The grass pellet making machine for Cattle Feed In Argentina

- Capacity: 5T/H

- Raw materials: alfalfa

- Finished pellet: 6-8mm milking cattle feed

- Total power: 220KW

- Workshop size: 9m*5m*15m (L*W*H)

The grass pellet machine in Cattle Feed Manufacturing Plant In Uzbekistan

- Capacity: 4-6T/H

- Raw materials: hay grass, alfalfa, corn, soybean meal, and other grain

- Finished pellet size: 3-8mm ruminant feed

- Workshop size: 6m*3m*7m (L*W*H)

The grass pellet machine in Cattle Feed Processing Plant In America

- Capacity: 10-12T/H

- Raw materials: grass, corn, wheat bran, soybean meal, and hemp

- Finished pellet size: 4-8mm cattle feed, sheep feed, and chicken feed

- Workshop size: 16m*7m*7.5m (L*W*H)

The grass pellet mill In South Africa

- Capacity: 10-12T/H

- Raw materials: corn, soybean meal, 50% grass, and other grain

- Finished pellets: powder, and 3mm, 5mm, and 8mm feed pellets

- Workshop size of the plant (L*W*H): 19m*6m*25m

The grass pellet machine for chicken and cattle in Saudi Arabia

- Project name: Animal feed factory project in Saudi Arabia

- Raw materials: grass, corn, soybean meal

- Finished pellet size: 1-8mm cattle feed and chicken feed

- Workshop size: 16m*8m*12m (L*W*H)

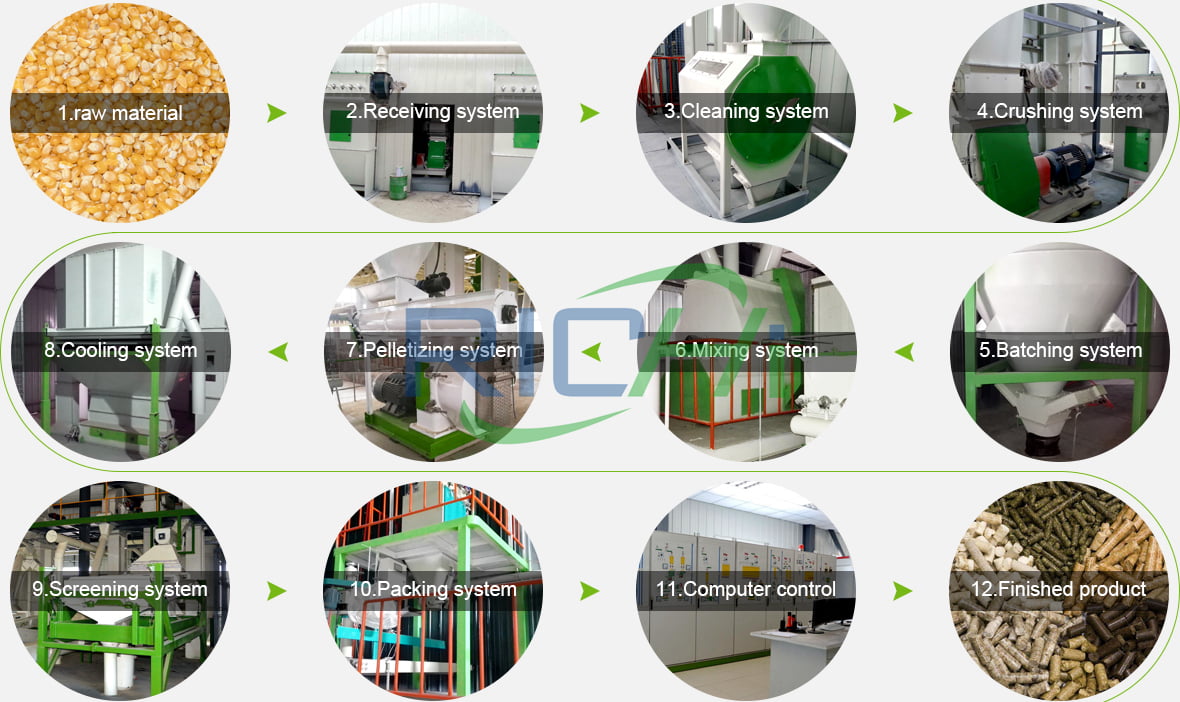

The working processes of the ruminant feed pellet production line

The grass pellet mill is mainly used to produce feed pellets of ruminant animals. The ruminant feed pellet production line mainly includes raw material receiving and cleaning system, crushing systems, batching and mixing system, granulating system, cooling system, screening system and finished product packaging system. According to the specific needs of customers, we can improve the design of a complete ruminant feed pellet production line suitable for cattle and sheep.

01 Crushing process of the ruminant feed pellet production line

A Crusher machine is an important machinery for raw material crushing and processing. The crusher can grind raw materials to the required size. If you manage a large feed granulation plant, the water drop crusher is the ideal choice.

02 Mixing process of the ruminant feed pellet production line

Mixing is one of the processing methods in the ruminant feed pellet production line. Proper mixing will increase the uniformity of diet and improve the quality of feed. RICHI provides two types of feed mixer machines – biaxial feed mixer machines for granular materials and spiral bel feed mixer machines for powder materials. They are all equipped with atomizing spray system, which can add the required liquid to improve the quality of feed pellets.

03 Pelletizing process of the ruminant feed pellet production line

The grass pellet mill is the key equipment of the ruminant feed pellet production line. CPM model, gear drive, and ring die design are widely used in the production of large-yield feed granules.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

04 Cooling and screening process of the ruminant feed pellet production line

After the pellets come out of the grass pellet making machine, the temperature is high and the moisture is large, so the cooling machine is required for cooling. The rotary screener is used for screening and grading feed pellets. After this process, you can obtain qualified feed granules without powder.

05 Packaging process of the ruminant feed pellet production line

For packaging, storage, transportation, and sales, the automatic packaging machine can accurately weigh and package feed pellets.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

RICHI Machinery – professional manufacturer of grass pellet mill

The grass pellet machine is mechanical equipment to press the grass into cylindrical feed granules suitable for cattle, sheep, pigs, etc. The grass pellet machines produced by RICHI Machinery use advanced technology to improve production efficiency, ensure the quality of the granules, improve technology, compact mechanism, and simple structure, and one machine can be used for multiple purposes, so as to ensure the pelleting at any time without any obstacles. It is suitable for all seasons and pelleting at any time and anywhere

More than 25 years of experience

RICHI Group has our own manufacturing plant and enjoys a good reputation. Also, we have our own factory. Welcome to RICHI factory!

High-quality assurance

As a manufacturer, RICHI always chooses high-quality materials to prolong its service life and improve efficiency. The grass pellet making machine sold by RICHI uses stainless steel as the main material. It has good corrosion resistance.

Customer-oriented service RICHI grass pellet mill

- Send us your requirements. We can provide you with cost-effective layout plans for free.

- Provide sample test free of charge.

- We test raw materials free of charge. You can send the sample to us, and we will provide you with the data.

- We design process flow charts for you free of charge. If you have an existing factory, you can provide the area for detailed design.

- We have a professional service team to provide you with the most appropriate equipment and satisfactory service.

- We provide complete installation and staff training for free, so your workers can operate the equipment correctly and smoothly.

- We have an experienced and skilled R&D team to continuously improve the configuration and technology.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

FAQ about the grass pellet mill

How to maintain the best performance of the grass pellet machine?

The grass pellet mill’s motor adopts an energy-saving and environment-friendly motor, and the triangle decompression starting control cabinet has a small starting current and low power consumption. The increase in the outer diameter of the press roll of the grass pellet making machine makes it difficult for the temperature generated by extrusion to be transmitted to the bearing chamber, so as to ensure that the bearing works at a low temperature. The bearing also increases the pressure capacity. The press roll is fully sealed against dust to ensure that grease does not spill out. The utility model prolongs the service life of the press roll bearing, improves the working efficiency, and reduces the cost. The mold and pressure roller of the grass pellet machine is made of alloy steel and advanced heat treatment technology, which improves the service life. As the shape of the grass pellet machine’s products is granules, the volume is compressed, the storage space is saved, the transportation is convenient, and the transportation cost is reduced.

Regularly check the parts of the grass pellet making machine once a month to check whether the worm gear, worm, bolts on the lubricating block, bearings, and other moving parts rotate flexibly and wear. If any defects are found, they should be repaired in a timely manner and should not be used reluctantly. The grass pellet making machine shall be used in a dry and clean room, and shall not be used in places where the atmosphere contains acids and other corrosive gases flow. After the use of the grass pellet machine is completed or when it is stopped, take out the rotary drum for cleaning and brushing the remaining powder in the bucket, and then install it properly to make preparations for the next use.

If the machine is not used for a long time, the whole body of the grass pellet mill must be wiped and cleaned, and the smooth surface of the machine parts must be coated with antirust oil and covered with a cloth.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production