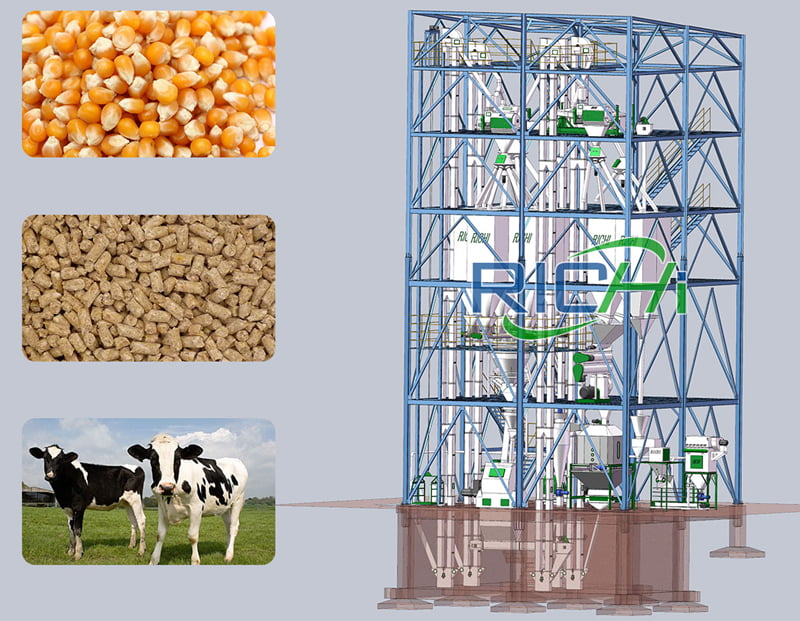

Ruminant feed pellet production line can produce cattle, horse, camel feed pellets, etc. The whole line is compact in design, reasonable in structure, meets environmental requirements, and can be customized according to customer requirements. With 27 years of experience, RICHI Machinery can offer you a complete turnkey service, including design, equipment production, delivery, installation, training, and after-sales services.

+86 18574103366

It is applicable to the production of ruminant feed, such as cattle feed and sheep feed. Our animal feed equipment is customized according to the needs of customers and can fully meet their needs. If you need, please contact us directly to discuss relevant details. RICHI can provide customers with a customized ruminant feed pellet production line.

Capacity:

1-100T/H

Main Power:

45-1700KW

Capacity:

1-100T/H

Main Power:

45-1700KW

Capacity:

1-100T/H

Main Power:

45-1700KW

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The grass pellet mill is a special forced feeding structure for forage in the pressing room. The main drive for uniform feeding is a high-precision gear drive, and its output is about higher than the belt drive type. The ring die adopts a quick-release hoop-type transmission part, which adopts imported high-quality bearings and has a long service life. Low noise feeding control adopts frequency conversion speed regulation to ensure uniform feeding. Convenient operation, reliable sealing, stable torque, high vibration absorption, isolation strength, and low labor intensity.

The specific parameters of the grass pellet mill are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The ruminant feed pellet production line mainly includes raw material receiving and cleaning system, crushing systems, batching and mixing system, granulating system, cooling system, screening system and finished product packaging system. According to the specific needs of customers, we can improve the design of a complete ruminant feed pellet line suitable for cattle and sheep.

01 Crushing process of the ruminant feed pellet production line

A Crusher machine is an important machinery for raw material crushing and processing. The crusher can grind raw materials to the required size. If you manage a large feed granulation plant, the water drop crusher is the ideal choice.

02 Mixing process

Mixing is one of the processing methods in the ruminant feed pellet production line. Proper mixing will increase the uniformity of diet and improve the quality of feed. RICHI provides two types of feed mixer machines – biaxial feed mixer machines for granular materials and spiral bel feed mixer machines for powder materials. They are all equipped with atomizing spray system, which can add the required liquid to improve the quality of feed pellets.

03 Pelletizing process

The grass pellet mill is the key equipment of the ruminant feed pellet production line. CPM model, gear drive, and ring die design are widely used in the production of large-yield feed granules.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

04 Cooling and screening process of the ruminant feed pellet plant

After the pellets come out of the grass pellet mill, the temperature is high and the moisture is large, so the cooling machine is required for cooling. The rotary screener is used for screening and grading feed pellets. After this process, you can obtain qualified feed granules without powder.

05 Packaging process of the ruminant feed pellet production line

For packaging, storage, transportation, and sales, the automatic packaging machine can accurately weigh and package feed pellets.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

RICHI Machinery, as a manufacturer of ruminant feed pellet lines, can provide you with various designs according to your different needs. With more than 25 years of experience, RICHI Machinery owns its factory and professional technical team. The ruminant feed pellet production line can produce 2-12mm feed pellets from corn, grass, wheat bran, rice bran, maize meal, soybean meal, sorghum, barley, cassava meal, oat, etc.

Cattle are ruminants. Therefore, under modern breeding conditions, the food structure of cattle is generally based on forage and concentrate feed, and other roughages are properly matched. The grass is mainly fresh grass, hay, tree stems, and leaves, and common coarse materials include distiller grains, bean curd dregs, etc. Then, forage or roughage is generally easy to find, and you can directly purchase it from the raw material supplier. Then, how to mix cattle feed. Some of these farmers may not know. Next, we will explain the preparation method of cattle feed.

First of all, we should understand the nutritional structure and composition of cattle feed. After knowing the nutritional structure and composition of raw materials, purchase corresponding raw materials and prepare them in proportion. Our most common cattle feed includes full-price feed, concentrated feed, pellet feed, and premix feed. The most nutritious and convenient feed is full-price feed. Its main components are vitamins, trace elements, amino acids, calcium, phosphorus, salt, fattening agents, anti-disease drugs, etc. Although the full-price material is easy to use, it also has a great disadvantage in that multiple processes are added, resulting in very high prices and often not obvious results.

Some breeding friends do not have the awareness of the reasonable proportion of various feed materials, but just mix the proportion of various raw materials randomly according to their own ideas. This practice is actually wrong, because if the proportion of various feed materials cannot be reasonably matched, some raw materials will be consumed too much, and some raw materials will be consumed too little, which will lead to waste of raw materials.

In today’s breeding situation, if the cost of feed is too high and the effect is not obvious, you will find that you have not earned a penny or even lost money in a breeding cycle. Therefore, the slightly larger farmers have begun to change their minds and prepare their own cattle feed. And feed production equipment is also easy to purchase. Breeders only need to buy the most core raw materials in the feed, and then mix corn, wheat bran, soybean meal, rapeseed meal, cotton meal, etc. in proportion to make the most convenient full-price feed. The self-ingredients can not only save some costs, but also ensure the effect, and the animals grow faster.

The feed pellet making machine is the vital machinery of the whole ruminant feed pellet plant. According to the unique digestive physiological characteristics and feed nutrition requirements of ruminants, cattle and sheep feed is very different from pig and poultry feed in terms of feed formula and feed preparation technology.

The ruminant feed includes the feed of ruminant animals such as cattle, sheep, horses, and camel. The ruminant feed is divided into concentrate and a total mixed diet. The raw materials of ruminant feed mainly include corn, wheat, barley, soybean meal, and other grain raw materials (similar to livestock feed), as well as coarse fiber raw materials such as grass, hay, and straw.

Ruminant feed pellets are characterized by coarse crushing fineness (4-8mm mesh diameter), low requirements for ripening and conditioning (single-layer conditioner is used for pelletizing), and large diameter of finished pellets (about 2-12mm in diameter).

A grass pellet mill is mainly applicable to the processing of coarse (fiber) feeds such as hay, beet residue, and various straws. It is also equipped with arch breaking feeding silo. As forage and other materials are prone to arching, there is a broken arch feeding bin, which is convenient for subsequent granulation.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

—— ABOUT US ——

RICHI Machinery, located in Zhengzhou, Henan Province, is an industrial group specializing in feed pellet machinery, biomass wood pellet equipment, organic fertilizer pellet machinery, and so on. For a long time, RICHI has invested in research and development and has introduced internationally advanced process equipment. Based on this, RICHI constantly improves and optimized every detail of product design and production to ensure the reliability of product quality and the perfect completion of customer projects. All of the equipment have passed the technical appraisal and recognition of the relevant national departments and enjoy a good reputation in the market.

WHATSAPP

+86 18574103366

Feed Machinery Design And Production

RICHI Machinery has a professional technical team. On the basis of site survey and planning, provide customers with a detailed project design scheme, feed equipment list, project cost, design site foundation drawings, and design special feed production process.

Feed Machinery Installation And Training

RICHI Machinery has a complete technical training and guidance system. After installation, professional engineers will train operators and guide the handling of common problems to ensure the stable operation of the system.

After Sales Service

RICHI Machinery always focuses on the field of machinery processing and has a modern and information-based after-sales management system and a professional and highly-skilled after-sales service team from the supply of common accessories, and equipment maintenance to repair.

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production