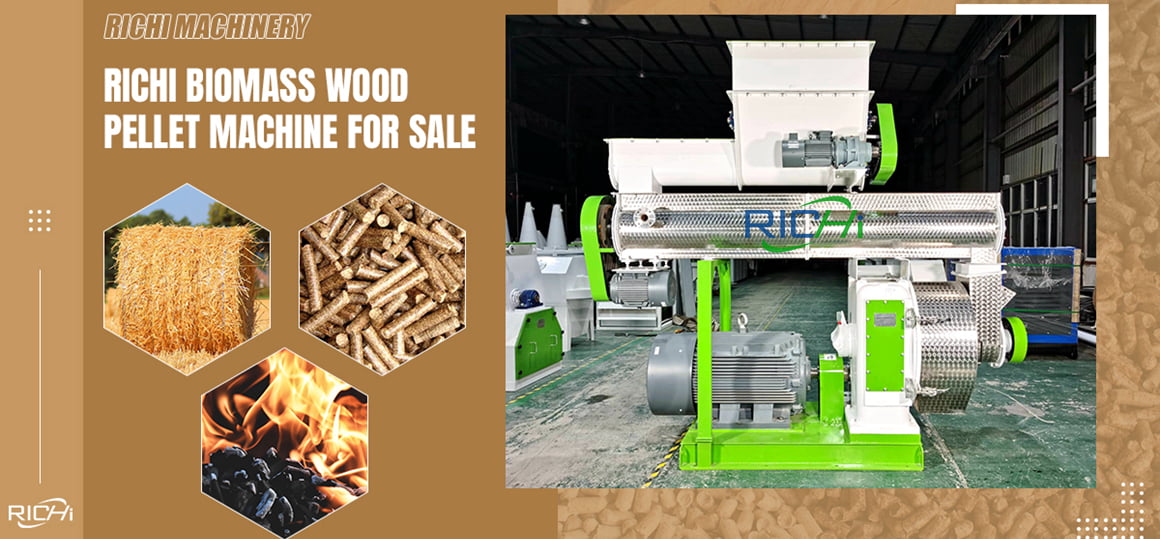

Sawdust pellet making machine

The sawdust pellet making machine from RICHI Machinery is used to produce smooth, hard, high-density and high calorific value sawdust pellets. Now, sawdust pellets have been widely used in power stations for commercial purposes, as well as pellet furnaces/fireplaces/boilers for household heating. As a new renewable resource, sawdust pellets have high economic value and huge market prospects. If you have a project with a large amount of sawdust, it is a very wise investment to buy a sawdust pellet making machine.

- Capacity: 0.5-10t/h

- The size of finished pellets: 6-12mm

- Raw materials: wood harvesting residue, wood processing residue, wood shavings, forestry wastes, log, branch, twig, wooden blocks, wood chips, wood sawdust, wood bran, bamboo shavings, etc.

+86 18574103366

Video- show how to make sawdust pellets

The sawdust pellet making machine is a ring die machine. Their function is to press crushed raw materials into pellets. The raw materials of sawdust pellets are various, including various crop straws, peanut shells, weeds, sawdust, industrial waste wood, vegetable and fruit residues, etc. These raw materials are crushed and shaped into high-density, high heat particulate fuel. The shaped pellets can be used in fireplaces, boilers and biomass power plants.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Advantages of sawdust pellet machine

With low energy consumption and a high degree of automation, the sawdust pellet machine can save more labor costs for the factory. Two workers can manage the production line from production to packaging. The sawdust pellet machine can operate 24 hours a day, greatly improving the production efficiency of compressed sawdust particles.

The noise generated during the sawdust pellet working process is small, the dust is small, and there is no sewage and pollutant discharge, so as to ensure the sanitation of the production workshop.

The sawdust pellet making machine occupies a small area, and the service life of the motor is longer. The sawdust manufacturing machine is made of high-strength steel, and the exterior of the machine is coated with an environment-friendly coating. The transmission efficiency is high, the machine is not easy to wear and rust, and the maintenance cost is small.

The sawdust pellet mill is widely used in rural and urban areas, whether in agriculture or forestry. The waste residue generated in the production of the plant can be converted into biomass pellet fuel through the sawdust pellet plant.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

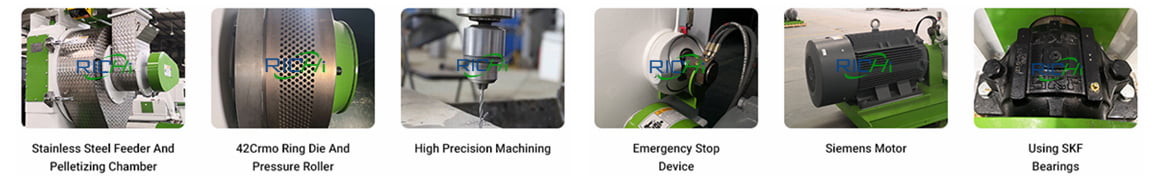

The Main Parts Of The sawdust pellet making machine

Force Feeder

The forced feeding consists of a motor, a connecting drive shaft, paddles (spiral blades), an observation door, a shell, etc. Open the observation door to observe and master the quenching and tempering effect of materials at any time, and it can be used as a manual feeding port for grinding the ring mold or feeding oily materials.

Ring Die And Roller

The ring die has many uniformly distributed small holes. In the granulation process, materials are forced to pass through the holes under the strong extrusion of the ring die and the pressure roller, so the ring die should have good strength and wear resistance. The pressing roller is used to extrude materials to the ring die and extrude them from the die hole.

Overload protection device

When hard foreign matters enter the pressing area or the material flow is too large, the pressure between the ring die and the pressing roller exceeds the normal working pressure. The bearing torque of the main shaft exceeds the normal torque and the shear force delivered to the safety pin also exceeds its strength limit. At this time, the safety pin breaks, causing the spindle to rotate and stop when it touches the travel switch.

Pelletizing Chamber

The main working parts of the pressing chamber are composed of the ring mould, two pressing rollers, feeding scraper, cutter and the adjusting screw for the gap between the mould rollers. The powder is drawn between the ring die and the press roll and formed in the die hole. The formed particles are cut into the required length by the cutter, and finally the formed particles flow out of the machine.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Parameters Of The sawdust pellet machine

Sawdust pellet making machine

Richi Machinery is specialized in selling sawdust pellet machines. Our sawdust pellet making machines are carefully designed for customers according to their actual requirements, which fully reflects the rationality, effectiveness, and applicability of the design, with large processing capacity, low wear and tear, and low operating costs. Low is its remarkable feature. Richi Machinery can provide overall solutions and turnkey services to meet different process requirements of customers.

- Model: MZLH series

- Pellet machine power: 37-280kw

RICHI Machinery can also provide you with 0.5-10T/H capacity equipment. The complete specific parameters are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The Cases Of The sawdust pellet machine

RICHI sawdust pellet making machine has been sold to more than 120 countries in the world, such as the United States and Thailand. We not only provide customers with equipment, but also provide them with free layout design. In addition, many customers visit our factory every year.

500-700KG/H sawdust pellet making machine

- Country: Ukraine

- Date: July 2019

- Model: MZLH320

- Raw materials: beech wood

- Size of the finished pellets: 6-8mm

- Workshop size (L*W*H): 16m*13m*6m

Indonesia sawdust pellet machine In The Wood Pellet Production Line

- Date: June 2018

- Capacity: 1t/h

- Model: MZLH420

- Raw materials: wood sawdust

- Size of the finished pellets: 8mm

- Workshop size (L*W*H): 20m*10m*15m

Australia Biomass Wood Pellet Machine For Sale

- Date: January 2021

- Model: MZLH520

- Capacity: 2-2.5t/h

- Raw materials: hardwood from wood offcuts, wood chips, and sawdust

- Size of the finished pellets: 6mm, 8mm

Canada sawdust pellet machine for sale

- Date: August 2018

- Capacity: 2-3t/h

- Raw materials: 50% moisture wood chips and 50% moisture sawdust

- Size of the finished pellets: 6-12mm pellets

5T/H sawdust pellet mill Of The Wood Sawdust Production Line

- Country: Austria

- Model: MZLH520

- Raw materials: sawdust and wood shavings

- Size of pellets: 4mm wood pellets

USA MZLH768 Wood Pellet Machine In Automatic Biomass Pellet Manufacturing Line Project

- Capacity: 10t/h

- Raw materials: wood wastes from furniture factories, paper mills

- Size of pellets: 6-12mm wood pellets

Working process of making sawdust pellets

Crushing system

Crush to standard size: 2-5mm in diameter. Use crushers to make suitable raw materials. 1-2mm raw materials can be directly granulated without crusher. Therefore, the crusher is optional for your granulation business. Whether you need it depends on your raw materials.

Drying system

Remove excess moisture. Use a dryer to remove excess moisture. It is better to ensure that the moisture content is less than 10%.

Pelletizing system

High quality and uniform sawdust pellets are made by mixing and pressing with the core part sawdust pellet machine.

Cooling system

The sawdust pellets are very hot when they first come out. You can use forced cooling of air-cooled silos to cool them.

Packaging system

Pour the cooled pellets into a bag and store them in a dry and well ventilated place to prevent the finished biomass pellets from being affected with moisture.

Do you know the granulation process now? Please consult us for more information on how to make sawdust pellets. Of course, you will get professional help from RICHI Machinery.

Moreover, the complete set of equipment for the wood pellet production line is not a fixed mode and can be customized according to different customer needs. The capacity of the wood pellet plant is 0.5-40t/h. Eucalyptus, birch, poplar, fruit wood, bamboo chips, and crop straw can all be used as raw materials. A complete wood pellet production line contains raw materials storage equipment, drum wood chipper, wood crusher machine, drum drying machine, wood pellet manufacturing machine, cooling machine, rotary screener, automatic packing machine, conveying equipment, and electric control cabinet. The wood pellet plant can be customized to your various needs.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Why use RICHI sawdust pellet making machine to make sawdust pellets?

01 Type of ring die with environment-friendly motor

The sawdust pellet machine with this working system is suitable for most biomass wastes. It can be widely used to manufacture biomass fuel particles. In addition, motors are more environmentally friendly than diesel-driven motors.

02 Efficient and good sawdust pellets – integrated production process

The sawdust pellet mill integrates PLC and cyclone dust remover. The automation rate is very high. The whole process is easy to operate and maintain. In addition, when the pressure wheel rotates and the die does not move, the torque will increase. The final sawdust pellets are of good quality.

03 Timed and quantitative lubrication system – 24 hours continuous operation

The lubricating system of the sawdust pellet machine is designed for timely and quantitative feeding under fully sealed conditions. There is no problem in working continuously for 24 hours.

04 Automatic feeding and discharging system

The RICHI pellet machine uses a screw feeder and a sealed discharger. The whole sawdust particle production process is automatic and fast. It does not require high skill to operate this machine. In addition, it does not require manual labor to operate.

RICHI Machinery pursues the purpose of product quality first. The main parts and wearing parts are made of high-quality wear-resistant materials, coupled with advanced processing technology. We provide various solutions for customers according to their needs, raw materials, production capacity, etc.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

FAQ of sawdust pellet making machine

What is sawdust pellet machine?

A sawdust pellet machine is a kind of equipment for granulating wood sawdust for heating purposes. Sawdust is the residue of paper plants, and furniture plants and more and more people are recycling the value of sawdust as a source of income. Sawdust is very common all over the world. A large amount of sawdust residue will be produced.

As we all know, a sawdust pellet mill was originally designed for processing feed. However, through customer feedback and our hard work, the sawdust pellet machine is suitable for processing sawdust, straw, and various kinds of grass. The sawdust granulator has the advantages of low price, low consumption, and high production capacity. It is a good choice for people, because the price of a sawdust pellet mill is very competitive, and it is very suitable for the owners of paper plants and furniture plants to use.

Why making sawdust pellet?

At first, the sawdust pellet making machine sold was very low, and everyone could afford it. Secondly, the benefits of finished sawdust pellets were huge, and they were widely used.

01

Economic benefits

Sawdust granulation can increase its bulk density, thereby improving storage and reducing transportation costs. The energy contained in sawdust is highly concentrated, providing fuel with very good energy quality, heat and minimum ash content.

02

Environmental protection

There are a large amount of sawdust residues. If not treated, it is likely to cause environmental pollution. At this time, processing sawdust can not only protect the environment, but also obtain economic benefits as a by-product.

What should pay attention in sawdust pellet production process?

Sawdust needs to be pretreated before making pellets. The moisture content should be about 15%, otherwise it will affect the quality and molding speed of pellets. The size should be smaller than the hole diameter, generally 4-5mm, otherwise the hole will be blocked and the sawdust pellets will be damaged. In addition, there are usually some impurities and foreign matters in the raw materials, which must be removed.

For pretreatment, you need a hammer mill to crush the large wood into small size, and a dryer to reduce the moisture content. However, a dryer is optional because the sawdust can be air dried.

After pretreatment, you can feed these materials into the sawdust pellet machine, sometimes with the help of a conveyor belt. The sawdust pellets produced by the sawdust pellet mill have high density, high hardness, smooth surface, and no cracks. They are cylinders with a diameter of 6-8mm and a length of 4-5 times the diameter.

Sawdust pellets are extruded from the sawdust pellet making machine at a higher temperature. You can use a counterflow pellet cooler to cool them, or place them in the open air to cool them. After that, you can put them in bags for storage and transportation. For mass production, packaging machine is necessary.

The common problems in the sawdust granulation process are the blockage and damage of the particle mold, overheating, high energy cost or poor particle quality, and high maintenance of the sawdust pellet making machine. In order to avoid the above problems in the production of sawdust pellets, high-quality sawdust pellets manufacturing machines are needed.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production