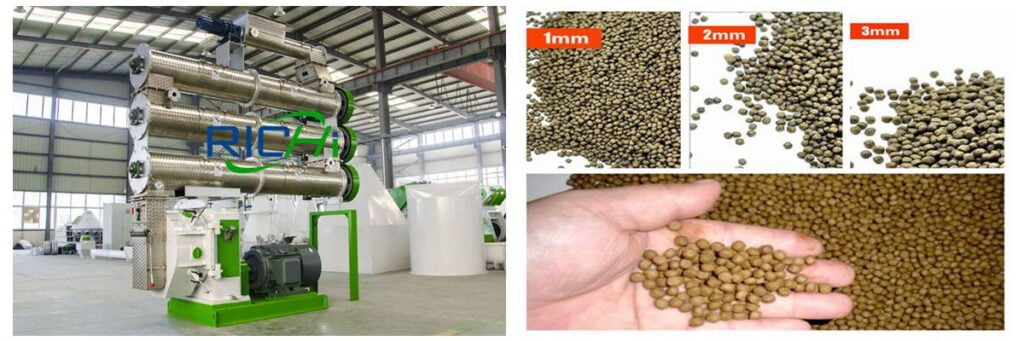

Shrimp feed pellet machine

The shrimp feed pellet machine is a ring die feed pellet making machine with triple-layer conditioners. During the processing, the materials are crushed and mixed, the starch is gelatinized, the protein is denatured, and the viscosity between the materials is enhanced under the effect of steam regulation. Finally, the materials are extruded through the ring die hole.

- Capacity: 1-42T/H

- Main power: 22-315KW

The video of the shrimp feed making machine

In the process of feed production, the shrimp feed pellet machine is the core equipment. We know that in feed processing, the purpose of granulation is to make pellets from finely crushed, dusty, and difficult-to-ship feed using heat, moisture, and pressure. Feed granulation with larger pellets can prevent feed components from being graded during mixing, transportation, and feeding, preserving nutrition and reducing waste.

Various capacities for shrimp feed pellet machine

In order to prolong and control the retention time of powder in the conditioner, three standard conditioners are stacked on top of the granulator, which is commonly referred to as the triple-layer conditioner pellet mill. This type of conditioner is characterized by a series connection and multiple steam injection ports. During operation, the powder passes through each conditioner in turn, extending the conditioning time of the powder. The materials can be more fully mixed with steam, which can increase the curing degree of the powder to about 40%.

SZLH250 shrimp feed pellet machine

Capacity:

0.1-0.2T/H

Main Power:

22KW

SZLH320 shrimp feed making machine

Capacity:

0.3-0.4T/H

Main Power:

37KW

SZLH350 shrimp feed machine

Capacity:

0.5-0.7T/H

Main Power:

55KW

SZLH420 shrimp feed machine

Capacity:

0.8-1.5T/H

Main Power:

110KW

SZLH508 shrimp feed making machine

Capacity:

2-2.2T/H

Main Power:

160KW

SZLH558 shrimp feed machine

Capacity:

1.5-2.5T/H

Main Power:

180/200KW

SZLH678 shrimp feed pellet machine

Capacity:

3-4T/H

Main Power:

220-250KW

SZLH768 shrimp feed making machine

Capacity:

4-5T/H

Main Power:

250/280KW

SZLH858 shrimp feed machine

Capacity:

5-6T/H

Main Power:

315/355KW

Specific parameters of the machine are as follows:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

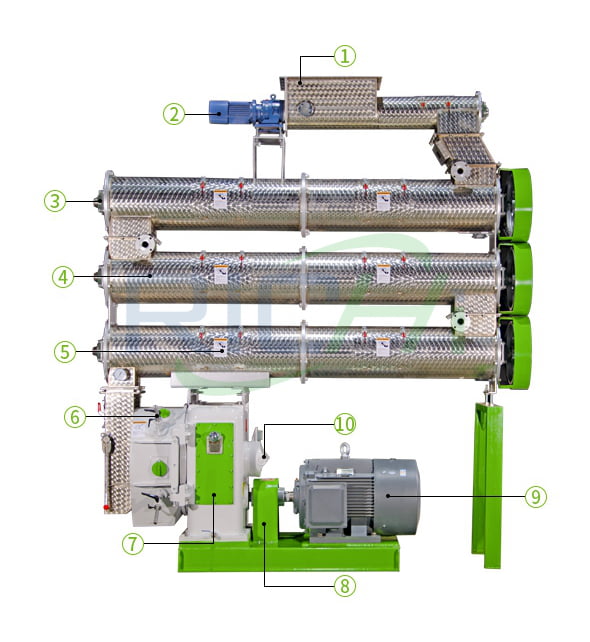

Parts of the shrimp feed pellet machine

01

Stainless steel feeder

Adopting advanced frequency conversion motor for feeding, with overload protection device. The variable frequency feeder can control the feeding speed so as to control the production progress.

02

Frequency conversion motor

The variable frequency speed regulation is to maximize the capacity of the shrimp feed pellet machine.

03

SKF Bearing

The bearing has the advantages of higher rated load, lower noise, greatly reducing the warranty cost, increasing the running time of the machine, etc.

04

Stainless steel conditioner

The core process of granulation is conditioning, which is to inject the proper amount of dry saturated steam into feed raw materials or powder to change the characteristics of powdered feed before granulation. Generally, the feed temperature after conditioning is 80-90℃, and the water content is 14-18%. The ideal conditioning time is about 30-45s.

05

Observe port

Open the observation port to view the effect of material modulation. In order to add or reduce saturated dry steam at any time.

06

Cutter adjusting handle

There are 2 cutters. By adjusting the handle, the distance between the cutter and the ring die can be changed, obtaining feed pellets of different lengths.

07

Gearbox

A direct gear transmission system is adopted, with the characteristics of stable transmission, high output, low noise, and convenient operation.

08

Shaft coupling

It is used to connect the two shafts together. When the machine is running, the two shafts cannot be separated.

09

Main Siemens motor

Variable frequency motor, adjustable speed of the ring die, adapt to different formula requirements, and better control of the material type.

10

Safety assembly

It is equipped with safety pins, and it can prevent overloading.

Gearbox

Siemens motor

Safety assembly

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The project cases of the shrimp feed pellet machine

RICHI Machinery is specialized in manufacturing equipment used for producing feed pellets and has independent intellectual property rights. Our company focuses on technology innovation and R&D, and the products and process technology are at the international leading level. RICHI pellet machines are exported to Indonesia, Thailand, Canada, Nigeria, Uzbekistan, Tanzania, Germany, etc.

Iran

Shrimp feed pellet machine in Iran

- Name: floating fish feed plant in Iran

- Capacity: 1.5-2t/h floating fish feed and 5-6t/h shrimp feed

- Feed pellet size: 1-12mm

- The installation period: 90 days

- The operating workers: 4-5 person

Uzbekistan

Uzbekistan shrimp feed making machine in Fish feed production line

- Total power: 298kw

- Raw material: fish meal, peanut meal, soybean meal, premix, etc

- Feed pellet size: 1mm, 2mm pellet

- Workshop size of this project: 8m*5m*14m (L*W*H)

- Operate workers in this line: 5-6 person

Ecuador

shrimp feed machine in the 1-2T/H fish feed production line

- Total power: 58kw

- Raw material: fish meal, bone meal, soybean meal, cotton meal

- Feed pellet size: 3mm shrimp and fish feed pellet

- Workshop size: 9m*6m*13m (L*W*H)

- Operate workers in this line: 2 person

China

Shrimp feed making machine in the fish feed production line for shrimp and prawn feed production

- Date: July 2016

- Capacity: 27-28T/H

- Feed Size: 1-4mm

- The installation period: 60 Days

- Control Mode: Automatic

FAQ about the shrimp feed pellet machine

Functions of conditioner in the shrimp feed making machine

Steam conditioning is the key technology in the pellet feed processing process. The conditioning effect directly affects the internal structure and appearance quality of the pellets. Steam quality and tempering time are two important factors that affect the tempering effect. High-quality dry saturated steam can provide more heat to improve the temperature of materials and gelatinize the starch. The longer the conditioning time is, the higher the starch gelatinization degree will be. The more compact the particle structure after forming, the better the stability and the greater the hardness will be. For ordinary livestock and poultry, the tempering temperature is kept at 70-80℃ by adjusting the amount of steam added, and the tempering time is controlled at about 30 seconds by changing the length, blade angle, and speed of the conditioner. For shrimp feed pellets, triple-layer conditioners are generally used for conditioning to increase the conditioning temperature and prolong the conditioning time. It is more conducive to improving the stability of shrimp feed pellets in water, and the hardness of pellets is correspondingly increased.

- The powdery materials are ripened. The ability of most animals to digest starch is very low, but they can digest cooked starch to a large extent. The conditioner can greatly increase the gelatinization degree of starch under the action of water and heat, and also promote the heat denaturation of protein in the material. The denatured protein is easy to be enzymatically hydrolyzed, thus improving the digestibility and utilization rate of pellet feed.

- Sterilize powder materials. Most pathogenic bacteria, such as Escherichia coli and Salmonella, are not heat-resistant. Tempering materials with a conditioner at a certain temperature can kill these bacteria and ensure the level of feed hygiene. Compared with drug disease prevention, this method of sterilizing materials with a conditioner has the advantages of low cost, no pollution, no drug residue, and side effects.

- The conditioning equipment can significantly improve the water resistance of the pellet feed. During the conditioning process, through the hydrothermal effect of steam, the viscous components of the material, gelatinized starch and denatured protein, can fully play the role of the binder, and can effectively bond other components around. Under the extrusion of the molding roller, the particles and particles combine more closely, so that the pellet feed becomes denser and has a smooth appearance, It is not easy to be eroded by water during feeding, which increases the stability of water.

- The quenching and tempering equipment can improve the granulation property of materials, increase the output, save energy consumption for granulation, and increase the life of the die and roll of the shrimp feed pellet machine. Through tempering, the material can be softened and more plastic. During the extrusion process with the die hole wall, the inner wall of the die, and the outer surface of the pressure roller, the friction force is reduced, which prevents a large amount of mechanical energy from being converted into heat energy during the granulation process, and at the same time, reduces the wear of the die and the pressure roller.

Generally, ordinary livestock and poultry feed plants can choose single shaft paddle type conditioner to ensure about 30 seconds of conditioning time, which can make the starch gelatinization degree reach about 20%, basically meeting the processing requirements of ordinary livestock and poultry feed. The aquatic feed factory shall select a three-layer conditioner to ensure that the ripening degree of the conditioned feed reaches more than 50%.

The key function and value of shrimp feed machine in feed production

The shrimp feed pellet machine is the key equipment in feed production. Its function and configuration directly determine the value of the fish feed production line. Under the same formula and process, whoever can improve the comprehensive efficiency of the shrimp feed making machine can win direct economic benefits for the feed factory. Therefore, how making the shrimp feed making machine plays a large role, in reducing the production cost per ton of feed, and improving the feed output and feed quality is a problem that every feed manufacturer needs to solve.

The key functions of the shrimp feed machine are mainly reflected in the following aspects:

- With corresponding processing technology (conditioning temperature, water content, compression ratio of ring die), it can adapt to feed granulation requirements of different materials and formulas.

- Under the condition of the same formula and feed specification, its pelleting yield is high, the powder ratio is low, the feed appearance quality is good (incision rate, uniform thickness, consistent length), the particle stability is good, and the feeding effect is good.

- The shrimp feed making machine operates stably, safely, and reliably, all interfaces are sanitary and sealed, the failure rate is low, and the working time of the ring molding roller is long. The high degree of automation and convenient maintenance.

Why Choose RICHI Machinery?

RICHI Machinery owns CE/ISO/BV certifications. RICHI Machinery has its own factory and professional production equipment. It is an industrial group that mainly focuses on animal feed pellet machinery, biomass pellet machinery, wood pellet machinery, etc. RICHI pellet machine is sold in many countries and regions in the world. We also provide various solutions for clients based on their different raw materials, production capacity, the kinds of pellets, etc.

RICHI Machinery also provides one-stop service. It has a professional system from structural design, equipment production, and installation to after-sales service.

Feed machinery structural design and equipment production

With more than 20 years of experience in the pellets equipment industry, RICHI Machinery can offer you a professional technical recommendation. On the basis of site surveys for customers, we can provide clients with a detailed project design scheme, design site foundation drawings, and so on.

Feed machinery installation and training

RICHI Machinery has a complete technology training and guiding system. Our technical workers can provide you with free training about how to operate the equipment, and how to do basic maintenance and protection of the equipment.

After-sales service

RICHI Machinery always concentrates on the production of pellet production equipment. And we have a professional and highly-skilled after-sales service team and a modern and information-based after-sales management system. From the supply of common accessories, and equipment maintenance to repair, we provide a one-stop service to release you of trouble.

RICHI Machinery, as an equipment manufacturer, would offer you all-around service. If you want to learn more about the shrimp feed pellet machine, just contact us directly and we are always here for you.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

CONTACT US

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production