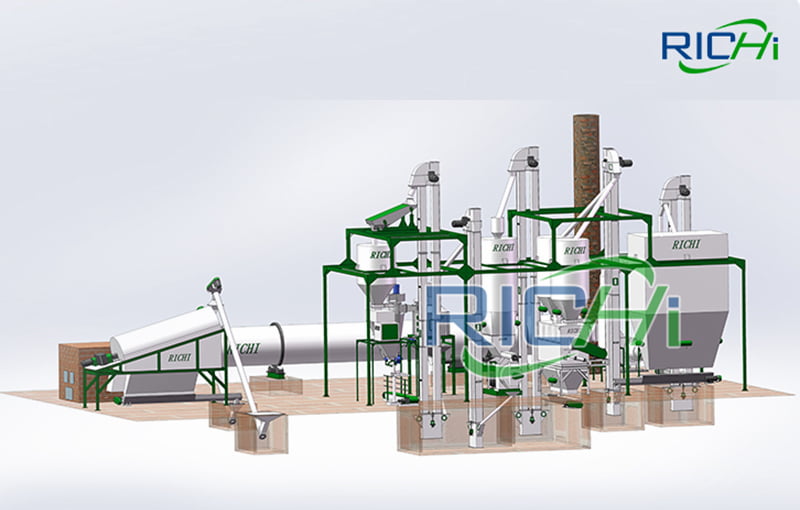

The project is a complete 2T/H wood pellet production line for a Romania client contracted by RICHI Machinery. The raw materials are all beech sawdust. The equipment is mainly used to produce wood pellets as biomass pellet fuel.

In Romania, forests cover an area of 6.33 million hectares. Sawdust is a kind of waste produced in the wood processing industry, which can be processed into pellets and used as biomass fuel. Romania has a temperate continental climate and needs biomass fuel. As one of the alternative energy sources, biomass energy is the most potential energy in the 21st century. The use of biomass pellets can save energy and is good for the environment. Therefore, investing in a wood pellet production line is very promising.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The client is a start-up company from Romania. The customer used to produce wooden blocks and big sticks. After that, they felt that the wood pellets had more development prospects and wider uses, so the Romania client decided to invest in a wood pellet production line. After comparison with dozens of manufacturers, they finally chose to cooperate with RICHI Machinery to build this wood pellet plant.

The Romania client began to have the idea of building a wood pellet plant several years ago. The customer is frustrated by deforestation, so he wants to find an alternative fuel. Wood pellets can just meet the needs of customers. The production line can produce ecological solid fuel from wood processing residues and agricultural residues. Therefore, after the wood waste is crushed into sawdust, it can be pressed into biomass particles, not only turning the waste wood into waste for recycling. The pellets can also replace coal for heating.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

In the beginning, the Romania client just wanted a 0.5-0.8T/H wood pellet production line. After many communications and negotiations between RICHI Machinery and the customer, the customer finally decided to cooperate with RICHI to build a 2T/H wood pellet plant. The project lasted four years. During this period, RICHI kept changing the design scheme to better meet customers’ needs.

This wood pellet plant was established and operated in Romania. It is designed and built to make wood pellets from beech sawdust. The wood pellets produced are mainly sold to local people in need of heating. The required production capacity is 2T/H. The optimum moisture content of this mixture should be 12%. The production process of wood pellets in this project includes crushing, drying, pelletizing, cooling, screening, and packaging.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

Wood pellets are biofuels made from sawdust or similar wood residues, and raw materials can be easily obtained. The Romania customer’s raw material is the sawdust of the beech tree. Romania has a temperate continental climate, which is very suitable for the growth of beech trees.

Beech wood is used to produce many useful products. The sawdust obtained in the processing of the beech trees is used to make beech wood pellets, which are good for renewable energy.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The sawdust is sent to the sawdust hammer mill by the belt conveyor for crushing.

The drum drying machine is used to dry the crushed wood waste materials to the suitable moisture content to pelletize.

The conveyor sends the sawdust that meets the pelletizing conditions to the wood pellet machine. Under the continuous extrusion of the roller, the sawdust is squeezed into the small hole, deformed into cylindrical pellets, and continuously squeezed. The pelletized material is cut into cylindrical pellets at the outlet of the wood pellet machine. The whole wood pellets manufacturing process is physical extrusion molding without adding any adhesive.

The temperature of wood particles produced by wood fuel pellets can reach 60-80℃, and the finished pellets are cooled to about room temperature in the cooling machine. The finished pellets from the wood pellet machine, through the rotating closed air feeder, are evenly stacked in the cooling box. The cold wind gets into the cooling box from the bottom of the cooling machine. The cold wind vertically passes through the material layer for heat exchange with the hot pellets and then is sucked out by the air suction system, so that the pellets can be cooled.

The qualified pellets would enter the next process, and the unqualified pellets would be returned to the wood pellet production process as raw materials.

The finished products from the discharge port are packed and warehoused by the automatic bagging machine.

The main equipment of the Romania wood pellet production line is:

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

01

The customer’s raw materials are mainly beech sawdust. But the customer wants to use other raw materials in the future. Therefore, Richi’s technician team designed two raw material inlets for customers. One can be directly used to put the beech sawdust, and then directly into the drying and pelletizing section. The other feeding port can be used to put wood blocks, chips, etc. The raw materials should be crushed first, and then enter the drying and pelletizing section.

02

In the crushing section, due to the limited budget of the Romania customer, Richi’s technicians adjusted the design scheme for the customer and replaced the wood chipper machine with a sawdust machine. This greatly saves the customer’s cost.

03

The finished product warehouse is equipped with a spiral slide. This is mainly used to prevent sawdust particles from breaking, so as to improve product quality.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

When designing solutions for Romania clients, RICHI Machinery also provides customers with a series of lists for future use.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

The EU has the world’s largest market for wood pellets. The EU produced about 13.5 MMT in 2015, accounting for about 50% of the global output. It is the world’s largest producer of wood pellets. Compared with the pellet factories in North America, the wood pellet production lines in the EU are mainly small or medium-sized. Most major pellets-producing countries have a considerable domestic market for residential heating pellets.

Recently, the continuous growth of pellets demand has further increased domestic production. The production of wood in Europe has grown steadily over the past five years. Therefore, sawmills can provide more wood processing by-products, including wood chips, wood shavings, and sawdust. With the increasingly fierce competition in the sawdust resource market, a wider range of sustainable raw materials has become necessary. In general, it is estimated that the production of wood pellets in the EU cannot keep up with the residential heating market and power generation demand. So investing in a wood pellet plant is worthwhile in Europe.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

EU countries are important wood pellets producing countries and consuming countries. The following are some of our biomass pellet production line projects in Europe. You can directly consult us for the details of the following wood pellet production equipment and wood pellet plant projects.

Germany

Austria

Poland

Iceland

RICHI Machinery has a professional technical team. On the basis of site survey and planning for customers, provide customers with a detailed project design scheme, wood pellet equipment list, project cost, design site foundation drawings, and design special pellet production process. RICHI Machinery has a complete technical training and guidance system. After installation, professional engineers will train operators and guide the handling of common problems to ensure the stable operation of the system.

RICHI Machinery can provide a complete wood pellet plant according to the different requirements of customers, and provide appropriate solutions according to different workshops. If you are interested in establishing your own wood pellet plant, just contact us!

WHATSAPP

+86 18574103366

The complete wood pellet production line is used to produce wood pellets from raw materials such as wood sawdust, wood shavings, logs, twists, and forestry residues. Wood pellets are new combustion energy. And more and more people are willing to use them. So investing in a production line is worthwhile. With this idea, the next question that should be considered is the cost to start a complete wood pellet production plant.

This is based on local raw materials and your own situation. Because some devices are optional, some need to be purchased, and some do not. Others can be bought by yourself. According to the configuration of the 1-20T/H wood pellet plant, the initial investment is about 15,000-200,000 USD.

If you’re not sure at first, a small wood pellet plant can be built first. If the income is good and the client source is gradually sufficient, you can expand the plant. From raw materials to wood pellets, wood chipper machine, wood dryer machine, and wood pellet machine are required. If the output is large, it is necessary to add some auxiliary equipment, such as cooling machine, automatic packing machine, etc.

With so much equipment, the following thing we should consider is the factory building. If you have enough vacant areas to build the wood pellet plant, you can save on rent. But if there is no production place, how much it costs to rent a place depends on the actual local conditions.

After the factory building problem is solved, you should again consider the issue of equipment funds. For a complete set of equipment, the specific price shall be determined according to the actual production needs.

After the equipment is purchased, the last thing you need to consider is labor. The number of labor required varies according to the output of the production line.

Therefore, if you want to invest in a wood pellet production line, you should first know what your raw materials are, how much production you need in a day, and whether you want to cool the wood pellets outdoors or cool them by machine. Only after all aspects are considered, can you equip a wood pellet plant that is most suitable for you.

In general, users choose different equipment and corresponding power according to their own production capacity and product types. RICHI Machinery specializes in equipment research and development for more than 25 years. If you want to know more, just send an inquiry to us.

—— GET A QUOTE ——

Pls Send Your Contact Information And Project Requirements, We Will Let Our Project Counselor Contact With You. In Addition, We Will Send The Quotation, Video, And Other Detail Information To Your Email, Pls Remember To Check Your Email!

Address

Longhai 2nd Rd & 10th St, Kaifeng City, Henan Province, China

Mail Address

enquiry@richipelletmill.com

Fax: 0086-371-63752859

Our Numbers

Whatsapp:+8618574103366

Telephone:0086-185-74103366

Open Hours

24 hours at your service Customize your private production